India’s Ship Recycling Industry: A Crucial Player in Green Steel Transition

India’s ship recycling sector has emerged as a key player in the global sustainability movement, offering significant potential to reduce carbon emissions in the steel industry. According to a recent Climate Group and PwC report titled Turning the Tide: Ship Recycling as a Source of Green Steel in India, the country’s ship recycling industry could play a transformative role in meeting the rising demand for sustainable steel production.

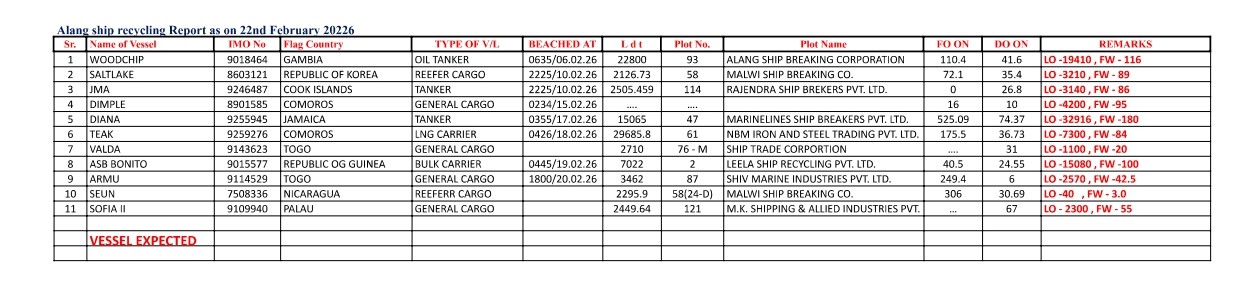

With the world’s largest ship recycling capacity, India processes nearly one-third of all decommissioned ships, primarily at Alang in Gujarat, a coastal hub known for its extensive ship-breaking yards. The report outlines how this industry, already pivotal in supplying raw materials, could further contribute to reducing the carbon footprint of India’s steel sector, which currently accounts for a staggering 12% of the country’s total greenhouse gas (GHG) emissions—nearly double the global average of 7%.

Steel Industry’s Emission Challenge

India’s steel production is heavily reliant on coal-based methods, a significant contributor to its carbon emissions. In this context, integrating scrap steel into the production process offers a viable solution. Scrap steel, primarily sourced from recycled ships, provides an environmentally friendly alternative to the traditional method of extracting iron from ore.

The report highlights that approximately 80-85% of a decommissioned ship is composed of steel. By increasing the recycling of this steel, India could significantly reduce its dependency on virgin raw materials and fossil fuels. Moreover, using scrap steel in crude steel production could conserve vast amounts of natural resources. For every tonne of scrap steel utilized, about 1,370 kg of iron ore, 780 kg of coal, and 270 kg of limestone are saved.

This shift not only reduces resource depletion but also slashes carbon emissions. “The circular nature of ship recycling supports sustainability while addressing the growing domestic demand for scrap steel,” said Atul Mudaliar, Director of Systems Change at the Climate Group, during the report’s launch in New Delhi.

Doubling Capacity: A Green Opportunity

The report underscores the importance of scaling up India’s ship recycling capacity to unlock its full environmental potential. It estimates that by doubling the current capacity by 2028, India could avoid up to 20 million tonnes of CO₂ emissions by 2040. Such a reduction would be a game-changer in the nation’s efforts to decarbonize its steel industry and align with global climate goals.

Achieving this ambitious target, however, will require significant upgrades to infrastructure and technology. New ship recycling facilities must adopt advanced processes to enhance efficiency and ensure compliance with international environmental and safety standards. These measures would not only improve the sector’s overall performance but also position India as a global leader in sustainable ship recycling.

Alang: The Heart of India’s Ship Recycling Industry

Alang, often referred to as the world’s largest ship-breaking yard, plays a central role in India’s ship recycling landscape. Over the past decades, this coastal town has dismantled thousands of vessels, contributing significantly to the global supply of scrap steel. However, to realize the sector’s full potential, Alang and similar hubs must overcome several challenges.

One of the primary concerns is the lack of modernized infrastructure. Despite being a global leader in terms of capacity, many facilities still operate using outdated techniques, which limits efficiency and poses environmental risks. Upgrading these facilities with state-of-the-art technology is crucial for optimizing the recycling process and minimizing environmental impact.

Additionally, the industry faces regulatory hurdles. The report calls for the implementation of robust policies and frameworks to standardize operations across ship recycling yards. Compliance with international guidelines, such as the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, is essential for ensuring environmental sustainability and worker safety.

Environmental and Economic Benefits

The transition to increased use of scrap steel in steel production offers multiple benefits beyond emission reductions. First, it would significantly lower production costs. Recycling steel requires considerably less energy compared to producing it from raw materials. This energy efficiency reduces operational expenses for steel manufacturers, making it an economically viable solution.

Moreover, the shift towards sustainable practices in ship recycling could create numerous job opportunities. Modernizing the sector would demand a skilled workforce to operate advanced machinery and adhere to stringent environmental standards. This could lead to the generation of thousands of new jobs, contributing to local economies, particularly in coastal regions like Gujarat.

On the environmental front, the benefits are equally compelling. Reduced dependency on coal and iron ore mining would alleviate pressure on ecosystems, preserving biodiversity and natural habitats. Furthermore, by preventing ships from being dismantled in unregulated, environmentally harmful ways in other countries, India can ensure that the global maritime industry operates more sustainably.

The Road Ahead

While India’s ship recycling industry has immense potential, realizing it will require concerted efforts from multiple stakeholders. The report emphasizes the need for collaboration between government bodies, industry leaders, and civil society to address existing barriers and implement effective solutions.

Policy interventions will play a critical role. The government must provide financial incentives to encourage investments in modern infrastructure and technology. Subsidies for adopting green practices, coupled with stricter regulations on emissions, could accelerate the transition towards sustainability.

On the other hand, industry players need to adopt a proactive approach. By embracing innovation and aligning their operations with global standards, they can enhance their competitiveness and contribute significantly to India’s climate goals.

Finally, raising awareness about the environmental and economic advantages of ship recycling is crucial. Public support and consumer demand for sustainable products can drive the industry towards greater accountability and transparency.

Conclusion

India’s ship recycling sector holds the key to a greener, more sustainable future for the steel industry. By leveraging its existing strengths and addressing current challenges, the country can significantly reduce its carbon footprint while driving economic growth. As the world transitions towards a low-carbon economy, India’s leadership in ship recycling could serve as a model for other nations, demonstrating how circular economy principles can be effectively integrated into industrial practices.

The path forward is clear: with the right investments, policies, and collaborations, India’s ship recycling industry can turn the tide in the global fight against climate change.

Author: shipping inbox

shipping and maritime related web portal