Bangladesh shipyards brace for recycling boom

Thirty ship-breaking yards and thousands of scrap workshops are dotted along 15 km of the coastline of Sitakunda, recycling about 38 per cent of the world’s dead ships and supplying steel scraps for Bangladesh’s thriving manufacturing industry.

Sitakunda, Bangladesh: On the southwest coast of Bangladesh, workers armed with gas torches, laser cutters and winches break apart the carcasses of the giant, old ships that are grounded on their sandy beach.

Thirty ship-breaking yards and thousands of scrap workshops are dotted along 15 km of the coastline of Sitakunda, recycling about 38 per cent of the world’s dead ships and supplying steel scraps for Bangladesh’s thriving manufacturing industry.

“Cutting ships is one of the riskiest jobs on earth,” said Jamal Uddin, 40, who works as a senior cutter in his local yard.

Over the last two decades, Uddin has seen many of his fellow workers in nearby yards suffer major burns and broken limbs while dismantling steel vessels that are sent to Bangladesh from rich, ship-owning nations.

With many old ships now nearing their end of life, the industry is bracing for a big, new economic shot in the arm.

According to a new report by the NGO Climate Group and consulting firm PWC, about 15,000 ships—or one in eight of the entire global fleet—will be recycled in the coming decade, twice the number of the past decade.

These older ships are heavy emitters, spewing out pollutants and planet-heating emissions, which have hastened the industry’s efforts to retire them, said Anand Hiremath, chief sustainability officer at GMS, which buys old ships and resells them to South Asian ship breakers.

Were it a country, the global fleet would have the dubious honour of being the world’s No. 6 emitter of planet-warming carbon dioxide.

The International Maritime Organization (IMO) has pledged to cut emissions by half by the year 2030 and turn it into a net zero emissions industry by 2050.

New global regulations aim to ensure that the dismantling of ships grows more safe and environmentally friendly as part of an industry-wide push to a more sustainable model.

But workers who cut and recycle ships said that the reform agenda does not promise them decent jobs or better pay.

“After a day’s back-breaking work, we hardly get the wages to cover our doctors’ costs or our kids’ school fees,” said Uddin, who chose not to name his employer, fearing repercussions.

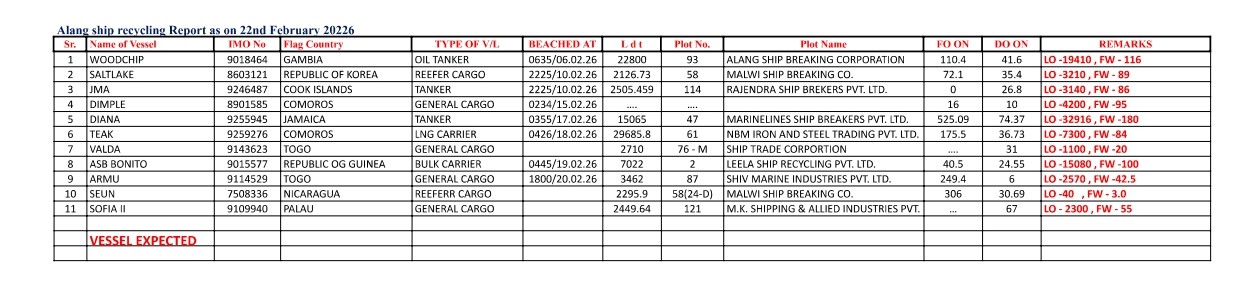

Most of the coming surge will be handled by yards in the Sitakunda region of Bangladesh or Alang in India’s Gujarat, which together account for about 70 per cent of global ship breaking.

Worker deaths are common, as is environmental harm with toxic chemicals seeping into the beach and water, harming marine life.

When workers use high-temperature torches to gouge a ship’s panels, accidents often happen, while exposure to hazardous substances such as asbestos risks long-term health impacts.

A Sitakunda shipyard fire killed seven workers in September.

Since 2009, 470 workers have been killed in South Asia’s more than 500 registered ship-breaking yards, according to the NGO Shipbreaking Platform, a coalition of environmental and labour rights groups headquartered in Brussels.

The industry employs at least 30,000 people – most of them low-paid, casual workers – in Bangladesh, India, and Pakistan.

“The recent accident showed once again that we still have to go a long way to ensure a safe workplace for ship-breaking workers,” said Fazlul Kabir Mintu of the Bangladesh Institute of Labour Studies (BILS), which works with yard owners and ship breakers to make their workplaces safer.

In June, the IMO is bringing in new regulations, known as the Hong Kong Convention, to address the risks that workers face and to govern how hazardous substances are managed.

The change will mean owners must document any hazardous substances in a ship before it goes for recycling.

Making jobs decent

Beyond increased safety, though, workers want better pay and benefits, said Mohammad Ali of the Bangladesh Metalworkers’ Federation (BMF) who set up the country’s first shipyard trade union.

Workers in Sitakunda’s yards usually make less than $5 for a precarious, eight-hour day. Most also work temporarily without ID cards and get no paid leave, Ali said.

So many of them must work additional hours to earn enough – putting them at still higher risk of accidents, he added.

When workers are killed in a workplace accident, they receive about 700,000 Taka ($5,740) in compensation.

That covers less than two years of an average household’s spending and does not include a pension.

Zahidul Haque, who is in his 70s, lost his son Abdur Rashid – a junior cutter when fire broke out in Pakiza Ship Yard about a decade ago.

“We received some compensation which was just 100,000 Taka ($820) back then – but with our sole earning member gone, we have no one to look after us,” he said.

Upgrading safety, waste management and labour rights requires buy-in from not only yard owners but also their governments, said Mohammad Mahbubur Rahman, whose HR Ship Management firm helps the yards get regulation-ready.

Whereas Bangladesh is lagging in its efforts to clean up the industry, Indian yard owners have benefited from government support as well as foreign funding, he said.

But rich companies – which own most of the ships – are also being urged to share some of the heavy transition costs.

“The world’s rich countries benefit from international shipping – and they need to care and act on how the ships are recycled and what happens to the workers,” said Ali from BMF.

Author: shipping inbox

shipping and maritime related web portal