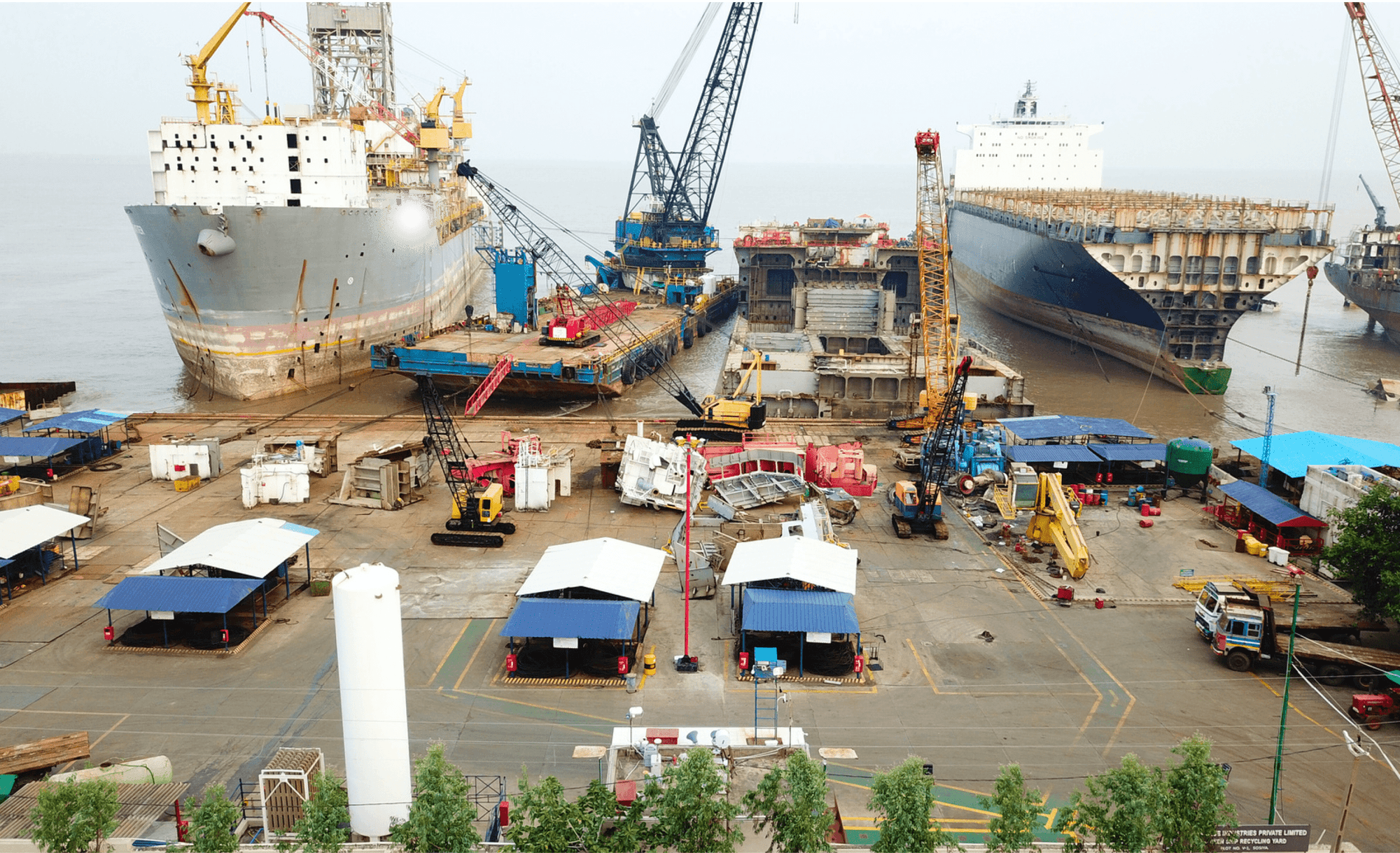

Alang Ship Recycling Has Improved in the Last Decade

Alang, located on the western coast of India, has been the largest shipbreaking yard in the world for decades. Stretching over 10 kilometres along the Gulf of Khambhat, it has long been a hub where old ships from all over the world are dismantled, their steel and other components sold off or reused. But for years, Alang was also notorious for its poor working conditions, environmental hazards, and safety concerns.

Over the last ten years, however, significant improvements have been made in the ship recycling industry at Alang, driven by international pressure, local initiatives, and global regulations. This transformation is gradually making Alang a model for sustainable ship recycling. Here’s how Alang has improved in the last decade and why it matters for the industry and the environment.

A History of Hazard and Opportunity

Alang’s shipbreaking yards started operating in the early 1980s and quickly became the go-to destination for dismantling decommissioned vessels. Ships are essentially floating cities filled with steel, electrical systems, machinery, and hazardous materials like asbestos, heavy metals, and oil residues. Alang provided a cost-effective solution for ship owners by offering cheap labour and few regulatory hurdles.

However, this cost-saving came at a price. In the early 2000s, Alang became infamous for its dangerous working conditions. Shipbreaking was done manually, often by workers without proper training or safety equipment. As a result, the yard saw frequent accidents, with workers suffering from injuries, toxic exposure, and even death.

The environmental toll was equally devastating. Toxic waste, including lead and mercury, seeped into the soil and ocean, polluting the local ecosystem and affecting the health of communities living around the shipyards.

But in the last ten years, several factors have converged to bring about significant changes in Alang.

Driving Forces Behind the Change

One of the major drivers of improvement in Alang has been pressure from international bodies, particularly after the adoption of the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships in 2009. Though the convention officially came into force only later, it set a framework for safe and sustainable ship recycling practices.

To comply with these standards, shipbreaking yards in Alang had to upgrade their facilities, improve worker safety, and implement environmentally sound practices.

Simultaneously, ship owners – particularly in Europe – began demanding more sustainable recycling processes. The European Union Ship Recycling Regulation (EUSRR), which came into force in 2018, requires EU-flagged vessels to be recycled in approved facilities. This regulation meant that Alang had to significantly improve its practices to attract business from European ship owners.

India’s government also realized the importance of cleaning up the industry. Several reforms and investments were made to modernize the ship recycling sector, including the introduction of new safety protocols, improved monitoring, and waste management systems.

How Alang Improved

1. Adoption of International Standards

Over the last decade, Alang has seen a major shift in the adoption of international ship recycling standards. Many yards in Alang have been certified under the Hong Kong Convention and are also compliant with the EUSRR. These certifications ensure that the yards follow proper procedures for dismantling ships, handling hazardous waste, and ensuring worker safety.

To meet these standards, yards have introduced concrete impermeable floors to prevent toxic chemicals from seeping into the ground. New waste management facilities have been set up to treat hazardous materials, and environmental monitoring has become more stringent.

2. Improved Worker Safety and Training

One of the most notable improvements has been in the area of worker safety. In the past, accidents and fatalities were common in Alang due to a lack of proper safety equipment and training. However, over the last ten years, shipbreaking yards have invested in better training programs and personal protective equipment (PPE) for workers.

Workers now receive proper training on how to dismantle ships safely and handle hazardous materials. The use of cranes and other machinery has also reduced the need for manual labor, which has helped to cut down on accidents.

In addition, first-aid centers and hospitals in the area have been upgraded to provide better medical care in case of accidents.

3. Environmental Safeguards

Environmental protection has also become a top priority at Alang. With global attention focused on sustainable practices, shipbreaking yards have made significant investments in waste management and pollution control.

New systems have been introduced to capture oil, fuel, and other toxic materials from ships before they are dismantled. These substances are then treated and disposed of in an environmentally sound manner.

Many yards have also adopted green recycling practices, which minimize the release of harmful substances into the environment. This includes the safe removal of asbestos, lead-based paints, and other toxic materials.

Alang has also set up monitoring systems to check water and soil quality regularly, ensuring that pollutants are not being released into the environment.

4. Technological Advancements

Alang has embraced modern technology to improve the efficiency and safety of shipbreaking operations. Many yards now use heavy machinery like cranes and cutters to dismantle ships, replacing manual methods that were slower and more dangerous.

Additionally, computer systems are being used to manage the recycling process, tracking materials and ensuring that hazardous substances are handled according to regulations. This has not only improved safety and efficiency but also increased transparency, making it easier to monitor compliance with international standards.

5. Socio-Economic Impact

While the focus on safety and sustainability has improved conditions at Alang, it has also had a positive socio-economic impact on the local community. With more stringent regulations in place, workers are earning higher wages and have access to better healthcare facilities.

The reputation of Alang has improved globally, attracting more business from international shipowners who are now more willing to send their vessels to be recycled at the yard. This influx of business has created more jobs and boosted the local economy.

Challenges and the Road Ahead

Despite the significant progress made, challenges remain. Not all yards in Alang comply with international standards, and there are still concerns about enforcing regulations. In some cases, smaller, less equipped yards continue to operate with lower safety and environmental standards, undermining the progress made by the larger, more compliant yards.

Moreover, while improvements have been made in worker safety and environmental protection, there is still work to ensure that these standards are maintained consistently across all yards.

Looking ahead, Alang has the potential to become a global leader in sustainable ship recycling. To achieve this, continued investment in technology, stricter enforcement of regulations, and ongoing training for workers will be crucial.

Conclusion

Alang’s transformation over the past decade is a testament to the power of international collaboration, regulation, and local initiative. What was once one of the most hazardous shipbreaking yards in the world is now emerging as a model for safer, cleaner, and more sustainable practices. The improvements made at Alang have not only benefited the environment and workers but have also strengthened the ship recycling industry, positioning it for a more sustainable future.

Author: shipping inbox

shipping and maritime related web portal